Development of Demand Response Control Device Independent of Energy Resource Manufacturers and Models

- Masaki Hosoya

- Yoshiki Sato

The Great East Japan Earthquake that struck on March 11, 2011, dramatically changed the environment surrounding Japan's electricity supply and demand. As the nuclear power plants ceased to operate one after another, the power shortage became so severe that the Ministry of Economy, Trade and Industry issued a power usage restriction order.

In order to improve this situation, the spread of small-scale energy resources such as solar power generation and storage batteries that are introduced on the consumer side is progressing. Energy management techniques that utilize IoT(Internet of Things) enable the bundling and integrated control of these technologies to adjust the supply-demand balance of electricity (demand response: hereinafter referred to as DR).

In order to make storage battery systems, which generally have a great influence on the adjustment of the balance of supply and demand, compatible with remote DR, it is necessary to modify them differently for each manufacturer and model. Therefore, TEPCO Energy Partner, Inc. has developed a mechanism for remote DR control of resources such as storage batteries independent of manufacturers and models. TAKAOKA TOKO has developed a DR control device (hereafter referred to as DR shiftTer*1), which is a device to realize this technology. We introduce new technologies that contribute to the improvement of Japan's power supply and demand.

*1) DR shiftTer is a registered trademark of Tokyo Electric Power Company Holdings, Inc.

Technology

Development of DR shiftTer using load following function of storage battery system

Despite the government's request to save electricity, most of the measures taken to save electricity so far were done by hand, such as reducing some lights and adjusting the temperature settings for air conditioning. This method not only increases the labor of consumers, but also has insufficient power-saving effect. The "DR shiftTer" developed by TAKAOKA TOKO uses the load following function of the storage battery system to remotely discharge the storage battery when the DR command is activated, making it a big step toward solving this problem.

From the viewpoint of environmental conservation, the use of renewable energy has progressed and is now connected to electric power systems. Since the amount of electricity generated depends on weather conditions and other factors, it is difficult to forecast the amount of electricity that can be supplied, and errors in forecasting the amount of electricity generated will more likely to occur than before the introduction of renewable energy. We believe that expectations for DR shiftTer will continue to rise in the future as well in terms of responding to sudden power shortages and excesses caused by deviations from forecasts.

Profile

-

Masaki HosoyaTechnology Development Division

Masaki HosoyaTechnology Development Division

Research and Development Center

ICT Technology Group -

Yoshiki SatoTechnology Development Division

Yoshiki SatoTechnology Development Division

Research and Development Center

ICT Technology Group

Use the load following function to enable discharge as required

Hosoya:It began in May 2017. Tokyo Electric Power Company Holdings Inc., consulted us to "develop a device together that control electricity resources, such as storage batteries of consumers, by remote DR. Tokyo Electric Power Company Holdings, Inc., and TEPCO Energy Partner, Inc. were considering building a supply and demand adjustment market in the power system reform, and we were asked for cooperation.

Sato:Conventionally we controlled DR remotely by customizing each energy resource individually. However, it is very difficult to install on this way. This was an order to improve the power supply and demand situation by promoting the widespread use of all models by controlling them with the same mechanism.

Hosoya:Why does remote control lead to an improvement in power supply and demand? The concept of VPP*2 is related to this. Our customers have small-scale energy resources, such as storage batteries and generators. However, the idea is to make these resources work like a power plant by integrating them. In order to achieve this, it is necessary to integrate and remotely control various storage batteries and generators, and DR shiftTer was developed for that purpose. The storage battery system is equipped with a load-following function to prevent exceeding the contract power of consumer equipment. This function converts the received power measured by the power-receiving-side wattmeter into an analog signal or the like, and discharges the storage battery for the amount that the received power value exceeds the set load follow-up threshold. By adding a DR shiftTer between the power meter on the power receiving side and the analog signal line that connects the storage battery system, when the power supply and demand becomes tight the DR shiftTer adds a calculated value that takes into account the DR command value to the received power value and notifies to storage battery system. A state that the load following threshold is forcibly exceeded is then created in this mechanism to perform discharging.

Sato:A command to add an offset is issued in response to a DR command from a remote location, and the controller called Eco.Web5 performs OpenADR*3 communication to receive this command. Since it also has a function to report the amount of power received, the remaining amount of storage battery, and the charge/discharge power of the storage battery in a one-minute cycle, the system of the host aggregator can check the DR control status and adjust the storage battery DR command amount. This controller is our previously developed product, and we have customized and reused the one that was conventionally used for building management. The development of DR shiftTer was realized by utilizing the technology that we cultivated./p>

*2) Abbreviation for Virtual Power Plant (Virtual Power Plant)

*3) OpenADR is a trademark of the OpenADR Alliance

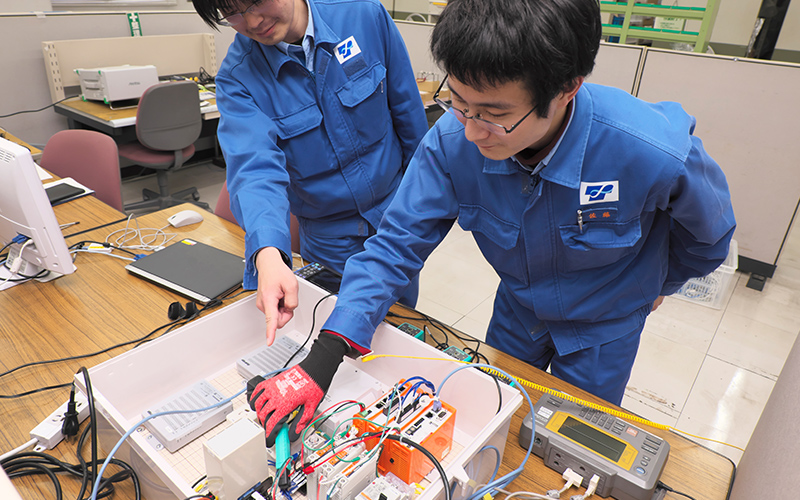

For improvement of the power supply and demand situation in Japan

Hosoya:Receive the command, change the power value, and then notify it. It may seem easy if you just learn the mechanism. However, we had to overcome many difficulties before development. What worried us first was the construction of the test environment. A wide variety of types of storage batteries and generators are actually used. Naturally, however, we cannot have all of them. Therefore, we developed our own simulator. A program assuming power consumption in a real environment was incorporated into a computer to create an environment in which simulations could be performed while considering multiple variables. As for the output values, we checked the locally received power and tried all possible values before actually installing them in the customer's equipment. It was November 2017. It was delivered in just half a year after the consultation.

Sato:After installation at the site, we continued brushing up. In terms of a major point, it is the addition of a function to prevent reverse power flow. We conducted simulations assuming all kinds of environments, but in an environment where the received power was even lower than expected, it was revealed that discharging causes the received power to become negative, leading to a reverse power flow in which electricity flows backward. To prevent reverse power flow, which may adversely affect the power system, we have added a function that allows you to set the discharge limit value for each installation environment.

Hosoya:It is true that there is still room for improvement, but we are confident in the high accuracy of control against DR command values. When we actually participated in the national demonstration test*4, the DR success rate was high, and we received words of praise from TEPCO Energy Partner, Inc. We have already completed installation of about 10 units at the plants of our customers, and we think that the number of installations will continuously increase in the future. For that reason, we would like to utilize feedback from the field in development to achieve even higher accuracy.

*4) Verification project commissioned by the Sustainable open Innovation Initiative (SII)

Sato:I think that improving accuracy is our obligation in terms of the nature of the product called DR shiftTer. In order to realize VPP, a large number of installations are required. Even if each error is small, it may not be possible to achieve the desired effect if it is accumulated by many DR shifTer. I would like to contribute to the improvement of accuracy and operability with the spirit of taking responsibility and influence. As a result, we believe that DR shiftTer will be selected by many aggregators, and that the situation of electricity supply and demand in Japan will improve significantly.

Latest articles

-

interviewProposal for new value via the first steel-tower-type full-color rendering illumination in JapanSince July in 2021, Prifoods Stadium in Hachinohe City, Aomori Prefecture has operated LED illumination equipment capable of the first steel-tower-type full-color light rendering in Japan. Takaoka Toko/Kyoya Denki/CADEC specific construction work consortium accepted an order for this equipment from Hachinohe City, and it was completed after nine months of work.

interviewProposal for new value via the first steel-tower-type full-color rendering illumination in JapanSince July in 2021, Prifoods Stadium in Hachinohe City, Aomori Prefecture has operated LED illumination equipment capable of the first steel-tower-type full-color light rendering in Japan. Takaoka Toko/Kyoya Denki/CADEC specific construction work consortium accepted an order for this equipment from Hachinohe City, and it was completed after nine months of work. -

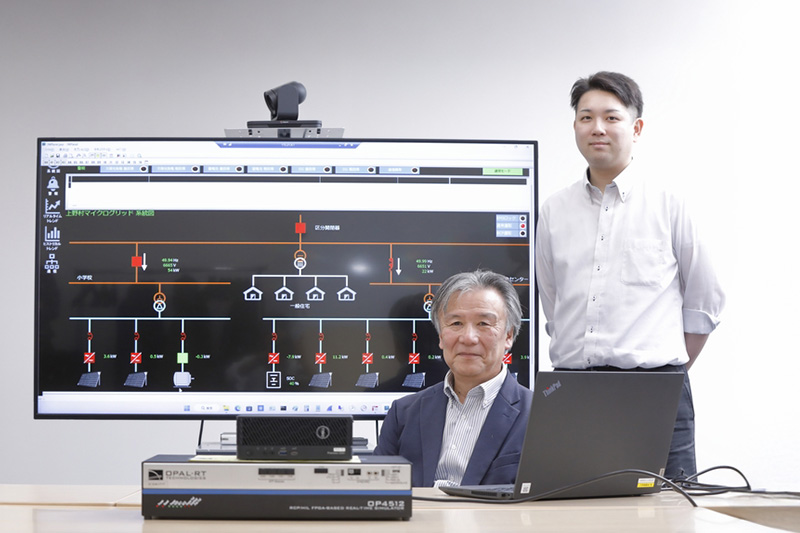

interviewBuilding a microgrid in Ueno Village, Gunma Prefecture, to Achieve Decarbonization and “Zero” Power Outages During a Disaster.The Sixth Strategic Energy Plan, a national policy, states that renewable energy is a main power source, and there is a need to expand the introduction of local power sources, including renewable energy. In recent years, the number of natural disasters in Japan has been on the increase, and a business continuity plan (BCP) is being emphasized for setting forth the methods and measures in advance to minimize the impact of an emergency and to ensure business continuity and a rapid recovery.

interviewBuilding a microgrid in Ueno Village, Gunma Prefecture, to Achieve Decarbonization and “Zero” Power Outages During a Disaster.The Sixth Strategic Energy Plan, a national policy, states that renewable energy is a main power source, and there is a need to expand the introduction of local power sources, including renewable energy. In recent years, the number of natural disasters in Japan has been on the increase, and a business continuity plan (BCP) is being emphasized for setting forth the methods and measures in advance to minimize the impact of an emergency and to ensure business continuity and a rapid recovery. -

interviewRecycling technology of transformer oil aiming to achieve carbon neutralityNowadays, the work involved in carbon neutrality and the establishment of a recycling society is essential in business activities. The same trend is observed in the field of transformer oil. The international standard for the quality of transformer oil has been revised; there is now no distinction in quality between new transformer oil and recycled transformer oil (hereinafter “recycled oil”) abroad, which allows them to be treated equivalently.

interviewRecycling technology of transformer oil aiming to achieve carbon neutralityNowadays, the work involved in carbon neutrality and the establishment of a recycling society is essential in business activities. The same trend is observed in the field of transformer oil. The international standard for the quality of transformer oil has been revised; there is now no distinction in quality between new transformer oil and recycled transformer oil (hereinafter “recycled oil”) abroad, which allows them to be treated equivalently. -

interviewWeCharge: EV charging management system that can be operated in large parking areasEfforts intended to achieve carbon-neutral levels have been made increasingly more often, which requires expansion of the EV charging infrastructure in order to propagate electric vehicles (hereinafter called “EV”).

interviewWeCharge: EV charging management system that can be operated in large parking areasEfforts intended to achieve carbon-neutral levels have been made increasingly more often, which requires expansion of the EV charging infrastructure in order to propagate electric vehicles (hereinafter called “EV”).