Lightning current measuring device for wind power generation equipment

- Hirofumi Fujioka

- Shigemi Sakai

- Osamu Kato

The amount of installed wind power generation equipment is expected to increase more than 15 times by 2040 with the starting year set to 2010. However, due to the increase in power generation capacity, the size of wind turbines has increased, and the frequency of lightning strikes has increased due to the height of the wind turbines. Along with this, lightning damage such as blade damage and splashing of wind turbines are occurring frequently due to winter lightning along the coast of the Sea of Japan, because the "energy (electric charge amount)" is unusually large worldwide.

TAKAOKA TOKO's lightning current measuring device plays a major role in accurately grasping the damage situation of wind turbines due to such lightning strikes and conducting maintenance inspections. When lightning strikes a wind turbine, it acquires the time of occurrence of the lightning strike, measures the peak value and amount of charge of the lightning current, and outputs a lightning strike contact signal that can be used to automatically stop the wind turbine using the measured values as output judgment conditions, etc.

To expand the introduction of renewable energy, we are improving lightning current measuring devices to meet the diversifying needs and standards of our customers. This section introduces the upgrading of functions from conventional products and future initiatives implemented in FY2018.

Technology

Improved measurement performance and functions that enable accurate understanding of failure causes

Our lightning current measurement equipment boasts the largest share of the domestic market, and as of FY2019, it has been installed in more than 25% of the total number of wind power generation equipment installed in Japan. Since around 2015, we have delivered more than 50% of the new installations, and in particular, we boast a market share of more than 90% in winter lightning areas along the Sea of Japan coast.

In FY2018, our lightning current measurement device improved the measurement performance and functions from the conventional product.

Offshore wind power generation equipment, for which demand is expected to grow in the future, are not easy for people to access and maintain. Therefore, we are planning to examine technologies for realizing remote maintenance of wind power generation equipment.

Profile

-

Hirofumi FujiokaTechnology Development Division

Hirofumi FujiokaTechnology Development Division

Research and Development Center

ICT Technology Group

Chief -

Shigemi SakaiEnergy Solution Business Headquarters

Shigemi SakaiEnergy Solution Business Headquarters

Power Equipment System Manufacturing Department

Protection & Control Equipment Design Group

Chief -

Osamu KatoPower Equipment & System Business Division

Osamu KatoPower Equipment & System Business Division

Power Equipment Infrastructure Sales Department

System Sales Group

Deputy section manager

Designing devices to meet diversifying needs and standardization

Sakai:Our lightning current measuring device uses a current sensor, called a Rogowski Coil, installed at the base of the wind turbine tower to measure the peak value and charge amount of the lightning current as values. GPS satellites can also be used to obtain accurate lightning strike times. It also has a function to collect lightning data remotely and a function to notify the occurrence of lightning strikes by e-mail.

Kato:In the background of the introduction of the email notification function, there was a request from the customer to grasp the measured lightning current in real time. It is used to make immediate decisions, for example, by considering the need for maintenance and inspection.

Sakai:In order to realize the measures for preventing the recurrence of lightning damage (shutdown and quick inspection in the event of a lightning strike) for wind power generation equipment proposed by the Ministry of Economy, Trade and Industry in 2015, the lightning current measuring device has a function to output a contact signal using the lightning current measurement value as an output judgment condition when a lightning strike is detected in the wind turbine. By using the signal to automatically stop only the wind turbines that were struck by lightning, and to continue operating the turbines that were not struck by lightning, it is possible to suppress the decline in the operating rate of the wind power generation equipment.

Fujioka: In 2018, we upgraded our lightning current measuring device from a conventional device to meet the requirements for further standardization.

- By setting the lower limit of the frequency band to 0.1 Hz, it is possible to accurately measure winter lightning current in the coastal area of the Sea of Japan, which has a long duration and large energy.

- A lineup of products with the maximum measurable current of 200 kA has been developed to support the measurement of large current exceeding 100 kA.

- The trigger-level has been reduced from 2% to 1% of the maximum measured current, and smaller lightning current can also be detected (when the maximum measured current is 100 kA).

- In addition to "OR conditions," "AND conditions" have been added to the judgment conditions for lightning strike occurrence contact signal output (current peak value and amount of electric charge) to enable more diverse operations.

- A lineup of products with power supply voltage of 230 VAC has been developed to meet international standards for wind power generation equipment.

Sakai:Since improvements in measurement performance have made it possible to measure the current peak value and charge amount of various lightning currents, it is now possible to identify more accurate causes of wind turbine failure and confirm the validity of lightning-resistant designs in order to investigate the causes of lightning damage.

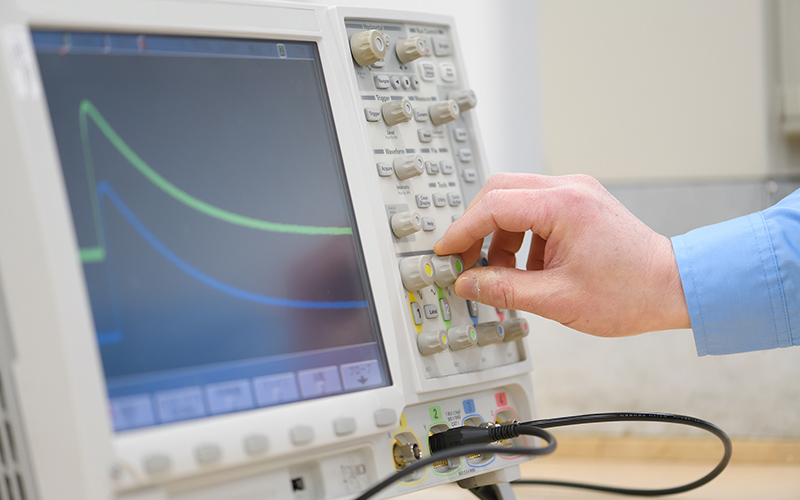

Fujioka:In verifying the lightning current measurement device, we struggled with measures against noises that would interfere with the measurement of lightning current. If the lightning current cannot be accurately measured due to erroneous detection, it will cause trouble for the customer. Regarding that point, we are making a careful verification. Conventionally, the lightning current waveform was recorded and verified for calculation of the peak current value and charge amount. However, verification after recording the waveform once is not allowed in the lightning current measuring device, which needs to be operated in real time Designing for noise elimination and real-time measurement was particularly difficult.

For entry into offshore wind business and further functional improvement

Kato:In the next version, we are considering the addition of a client function to connect with higher-level systems to meet customer needs.

Fujioka:In some cases where a wind turbine that had detected a lightning strike was stopped and inspected, no abnormalities were detected and there was actually no need to stop the turbine. Since it is not possible to generate electricity while it is stopped, the stoppage will lead to a decrease in the operating rate. As a solution, research is underway to determine whether or not a wind turbine is stopped by comparing and analyzing data from the system that constantly monitors the operation status of the wind turbine and lightning strike data in real time. In order to put it into practical use, it is necessary to connect our lightning current measuring device with the condition monitoring system, and we are considering it.

Sakai:Currently, wind turbines are mostly built on land, but the number of offshore wind power generation equipment is expected to increase in the future. Unlike onshore wind turbines, offshore wind turbines do not have restrictions on securing land or transportation, so they are increasing in capacity, that is, they are becoming larger. To promote the introduction of lightning current measuring device into this large offshore wind turbine, the current sensor must be reviewed. In addition, since it is difficult to access and inspect the wind turbine easily, there is a need for a maintenance technology that allows remote operation without human intervention, and we plan to investigate it in the future.

Fujioka:Since the wind turbine will basically be operated for 20 years after its construction, the lightning current measuring device, which is a part of the wind turbine, must also be maintained at all times. Therefore, the technology must be inherited within the company. I am involved in research while also placing an emphasis on nurturing the next generation.

In 2015, the Ministry of Economy, Trade and Industry announced measures to prevent the recurrence of lightning damage, and we feel more social responsibility for lightning current measuring devices.

In the future, efforts will be made to expand the system to offshore wind power generation equipment and improve the operating rate. Our goal is to reduce the number of factors that can lead to breakdowns in the design process, and to reduce customer losses caused by lightning strikes.

Sakai:Lightning current measuring devices may not be familiar to the public. However, I take pride in being a part of the important product design that prevents lightning damage to wind turbines, and I am proud of my work. I would like to keep in mind the design that will satisfy the needs of the customer.

Kato:In the future, we expect to compete with domestic and overseas manufacturers. We will leverage our top market share in Japan, including our entry into the offshore wind power business, and conduct sales activities to overcome the competition with our competitors.

Latest articles

-

interviewProposal for new value via the first steel-tower-type full-color rendering illumination in JapanSince July in 2021, Prifoods Stadium in Hachinohe City, Aomori Prefecture has operated LED illumination equipment capable of the first steel-tower-type full-color light rendering in Japan. Takaoka Toko/Kyoya Denki/CADEC specific construction work consortium accepted an order for this equipment from Hachinohe City, and it was completed after nine months of work.

interviewProposal for new value via the first steel-tower-type full-color rendering illumination in JapanSince July in 2021, Prifoods Stadium in Hachinohe City, Aomori Prefecture has operated LED illumination equipment capable of the first steel-tower-type full-color light rendering in Japan. Takaoka Toko/Kyoya Denki/CADEC specific construction work consortium accepted an order for this equipment from Hachinohe City, and it was completed after nine months of work. -

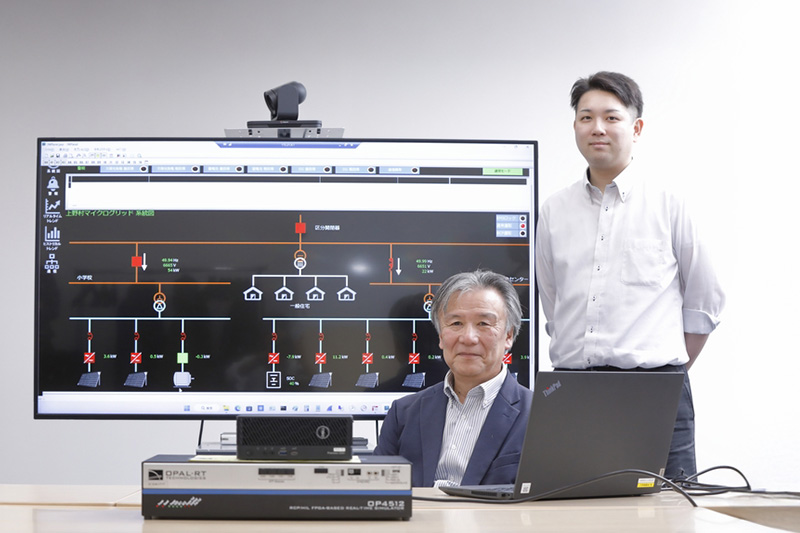

interviewBuilding a microgrid in Ueno Village, Gunma Prefecture, to Achieve Decarbonization and “Zero” Power Outages During a Disaster.The Sixth Strategic Energy Plan, a national policy, states that renewable energy is a main power source, and there is a need to expand the introduction of local power sources, including renewable energy. In recent years, the number of natural disasters in Japan has been on the increase, and a business continuity plan (BCP) is being emphasized for setting forth the methods and measures in advance to minimize the impact of an emergency and to ensure business continuity and a rapid recovery.

interviewBuilding a microgrid in Ueno Village, Gunma Prefecture, to Achieve Decarbonization and “Zero” Power Outages During a Disaster.The Sixth Strategic Energy Plan, a national policy, states that renewable energy is a main power source, and there is a need to expand the introduction of local power sources, including renewable energy. In recent years, the number of natural disasters in Japan has been on the increase, and a business continuity plan (BCP) is being emphasized for setting forth the methods and measures in advance to minimize the impact of an emergency and to ensure business continuity and a rapid recovery. -

interviewRecycling technology of transformer oil aiming to achieve carbon neutralityNowadays, the work involved in carbon neutrality and the establishment of a recycling society is essential in business activities. The same trend is observed in the field of transformer oil. The international standard for the quality of transformer oil has been revised; there is now no distinction in quality between new transformer oil and recycled transformer oil (hereinafter “recycled oil”) abroad, which allows them to be treated equivalently.

interviewRecycling technology of transformer oil aiming to achieve carbon neutralityNowadays, the work involved in carbon neutrality and the establishment of a recycling society is essential in business activities. The same trend is observed in the field of transformer oil. The international standard for the quality of transformer oil has been revised; there is now no distinction in quality between new transformer oil and recycled transformer oil (hereinafter “recycled oil”) abroad, which allows them to be treated equivalently. -

interviewWeCharge: EV charging management system that can be operated in large parking areasEfforts intended to achieve carbon-neutral levels have been made increasingly more often, which requires expansion of the EV charging infrastructure in order to propagate electric vehicles (hereinafter called “EV”).

interviewWeCharge: EV charging management system that can be operated in large parking areasEfforts intended to achieve carbon-neutral levels have been made increasingly more often, which requires expansion of the EV charging infrastructure in order to propagate electric vehicles (hereinafter called “EV”).