Expansion of line-up of stand-alone gas-insulated voltage transformers

for power plants and split-type transformers for outdoor use

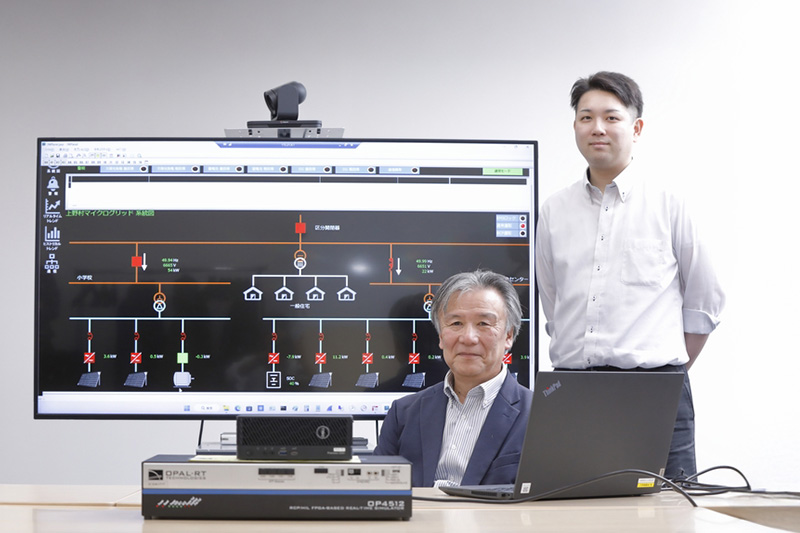

- Masamichi Murakami

- Koichi Kobayashi

In April 2020, electric power companies began separating power generation and transmission. In the past, electric power companies have been responsible for the "power generation division," which produces electricity, the "transmission and distribution division," which sends electricity to consumers, and the "retail division," which plans electricity rates and conducts sales and contract procedures. Of these, the separation of the power transmission and distribution division into separate companies is called the “separation of power transmission and distribution.” Since 2016, the liberalization of electricity has progressed, and electricity retailing for general households has been liberalized. Basically, anyone can generate and sell electricity. It is not easy to operate and manage the transmission and distribution of electricity delivered to the world, and it is also efficient for a single company to centrally handle it. For this reason, power transmission and distribution networks are still managed by local electric power companies, and new entrants to retail electricity businesses use these power transmission and distribution networks to sell electricity.

What is important here is that the transmission and distribution sector maintains equity, and in order to maintain a free electricity market, it is necessary for certain new power companies not to have an advantage in terms of cost or priority of each response. For this reason, companies responsible for power transmission and distribution are required to install measuring instruments for power trading, and TAKAOKA TOKO has commercialized a variety of measuring instruments to respond to changes in the electricity market.

Technology

Development of a "grounding type instrument transformer" that can be installed in a limited outdoor space and a "split type current transformer" that can be installed directly on a power transmission cable.

The electricity charge is calculated based on the amount of power used by the customer, but it is difficult to measure high voltage and high current, so a measuring instrument for power trading is required. With the liberalization of electric power, the power generation division needed to install this measuring instrument, but there was a problem with installation space.

Devices that measure electricity are so large that ordinary people cannot even imagine them. In order to measure voltages in excess of 100,000 V, a voltage-lowering device, called an instrument transformer, is first used to reduce the voltage to the voltage that can be handled by the instrument, followed by measuring with the instrument. This instrument transformer is very large. For this reason, TAKAOKA TOKO has developed a “grounding type instrument transformer” that is designed to be installed in a limited space and can be installed directly on the ground. In particular, we have increased the number of devices to handle voltages ranging from 110,000 to 275,000 V, which were not available in the conventional product lineup. Since SF6 (sulfur hexafluoride) gas is used as the insulator, it is generally called "SF6 gas-insulated installed voltage transformer."

We have also developed a "split type current transformer" insulated with epoxy resin, which can be installed directly on a cable for power transmission. This is also designed to change the large current flowing through the cable to a small current so that the measuring instrument can handle it. This is required in conjunction with the separation of power generation and transmission. Since use of the two-piece structure eliminates the necessity of cutting the cable to attach it, it is a great advantage that the installation cost and the burden of equipment repair can be reduced. Currently, products that support thicker cables are also being developed.

Profile

-

Masamichi MurakamiMetering Business Division

Masamichi MurakamiMetering Business Division

Oil & Gas insulated Instrument Transformer Manufacturing Department

Design group

Deputy section manager -

Koichi KobayashiMetering Business Division

Koichi KobayashiMetering Business Division

Mold Instrument Transformer Manufacturing Department

Design group

Deputy section manager

A stand-alone gas-insulated instrument transformer is proposed as a measuring instrument to be assembled in a limited space of power generation equipment.

Murakami:Originally, we made a gas-insulated grounding type instrument transformer for gas-insulated switchgear of up to 0.5 million volts. Based on this technology, the insulators (devices that insulate between the electric wires and the supporting posts) were stacked toward the top to meet the need for space-saving equipment that can additionally be installed independently in existing equipment. They were designed into a tower shape. The insulator of the instrument transformer is 3.5m in size, so adding the main body of the instrument transformer is about 5m as a whole. A long insulator is absolutely necessary for high voltage insulation. This time, we have incorporated a newly developed high-precision instrument transformer, especially for weighing.

In the past, TAKAOKA TOKO did not have a track record of providing such a single-installation type gas insulated voltage transformer, but by developing instrument transformers for voltages from 110,000 to 275,000 V, the product lineup has increased. We believe it is our strength to have a product lineup ranging from low pressure to ultra-high pressure using solid, liquid, and gaseous insulators. In the future, we intend to propose and develop optimal delivery methods while meeting the needs of our customers.

It is mandatory to install measuring devices at all power plants by around 2023, and until then, development will continue to meet the needs of customers. After that, periodic updates are started to maintain the accuracy of the measuring instruments, so the instruments are designed to be installed and removed as easily as possible.

Murakami studied machinery and materials at the university and was interested in designing and joined the company in 2007. Now, when he sees the devices he designed being actually used by customers, he says that he has a sense of reality and a sense of rewarding. Murakami also has some thoughts about a low-carbon society. It is to make products as small as possible and contribute even a little to low-carbon manufacturing. He also says he considers using environmentally friendly insulators.

Redevelopment of existing products based on Measurement Act

In addition, high-precision, high-current cables are also supported.

Kobayashi:Outdoor split type current transformer existed in TAKAOKA TOKO’s lineup before the separation of power generation and transmission. However, it was for a protective circuit, and was used as a device to detect a large current, such as a short-circuit current, when it flowed. We have improved the accuracy so that it can be used for measurement in conjunction with the separation of electricity generation and transmission, and we have reconsidered the design so that it can be tested based on the standards set by the Measurement Act set by the government.

In a household, electric power consumption is measured by a single meter. However, if the meter is used to measure it at a high voltage such as that handled at a substation, the meter may be damaged. For this reason, we are converting to a level that can be measured. However, if the accuracy of the conversion ratio is poor, the measured value will change significantly. Therefore, we are creating a device with high conversion accuracy.

In addition, we have newly developed a larger one to handle thick cables, which cannot be handled by conventional split type current transformers. Originally, the current transformer must be connected only after the cable has been disconnected. However, this split-type current transformer allows the current transformer to be installed later on the existing cable. This is a great advantage in terms of efficiency and cost.

There were many times when we struggled. The most important point is whether the accuracy measured at the plant is reproduced when installing on-site. If the divided body is combined on-site, the accuracy will change if the combination makes a slight shift. Therefore, it is designed to minimize misalignment even if anyone combines it. Then, after installation, it is structured so that it cannot be disassembled with a "sealing cover" to prevent unauthorized modification. If the "sealing cover" is opened, it cannot be used as a measuring instrument. The moment this is safely sealed, I feel relieved. Another feature of this product is that it contributes to noncombustibility. Insulators can be solid, liquid, or gaseous, but this product employs nonflammable epoxy resin for solid insulation.

Kobayashi studied power system engineering in the electrical department in college. He joined TAKAOKA TOKO with the desire to do important work that supports society. He says that when he gives instructions on how to install split current transformers, he feels a sense of "supporting the infrastructure." His future dream is to realize decarbonization in design. With the conventional method of making and verifying many prototypes, a large amount of CO2 is generated at the prototype stage. To suppress this, we are replacing prototypes with computer-based simulations and reducing the number of prototypes.

Work to support electricity, an important social infrastructure. We continuously make trial and error every day to keep such infrastructure protected firmly. While clearing the challenges of a low-carbon society for the future, the two engineers are working hard today with a sense of satisfaction.

Latest articles

-

interviewProposal for new value via the first steel-tower-type full-color rendering illumination in JapanSince July in 2021, Prifoods Stadium in Hachinohe City, Aomori Prefecture has operated LED illumination equipment capable of the first steel-tower-type full-color light rendering in Japan. Takaoka Toko/Kyoya Denki/CADEC specific construction work consortium accepted an order for this equipment from Hachinohe City, and it was completed after nine months of work.

interviewProposal for new value via the first steel-tower-type full-color rendering illumination in JapanSince July in 2021, Prifoods Stadium in Hachinohe City, Aomori Prefecture has operated LED illumination equipment capable of the first steel-tower-type full-color light rendering in Japan. Takaoka Toko/Kyoya Denki/CADEC specific construction work consortium accepted an order for this equipment from Hachinohe City, and it was completed after nine months of work. -

interviewBuilding a microgrid in Ueno Village, Gunma Prefecture, to Achieve Decarbonization and “Zero” Power Outages During a Disaster.The Sixth Strategic Energy Plan, a national policy, states that renewable energy is a main power source, and there is a need to expand the introduction of local power sources, including renewable energy. In recent years, the number of natural disasters in Japan has been on the increase, and a business continuity plan (BCP) is being emphasized for setting forth the methods and measures in advance to minimize the impact of an emergency and to ensure business continuity and a rapid recovery.

interviewBuilding a microgrid in Ueno Village, Gunma Prefecture, to Achieve Decarbonization and “Zero” Power Outages During a Disaster.The Sixth Strategic Energy Plan, a national policy, states that renewable energy is a main power source, and there is a need to expand the introduction of local power sources, including renewable energy. In recent years, the number of natural disasters in Japan has been on the increase, and a business continuity plan (BCP) is being emphasized for setting forth the methods and measures in advance to minimize the impact of an emergency and to ensure business continuity and a rapid recovery. -

interviewRecycling technology of transformer oil aiming to achieve carbon neutralityNowadays, the work involved in carbon neutrality and the establishment of a recycling society is essential in business activities. The same trend is observed in the field of transformer oil. The international standard for the quality of transformer oil has been revised; there is now no distinction in quality between new transformer oil and recycled transformer oil (hereinafter “recycled oil”) abroad, which allows them to be treated equivalently.

interviewRecycling technology of transformer oil aiming to achieve carbon neutralityNowadays, the work involved in carbon neutrality and the establishment of a recycling society is essential in business activities. The same trend is observed in the field of transformer oil. The international standard for the quality of transformer oil has been revised; there is now no distinction in quality between new transformer oil and recycled transformer oil (hereinafter “recycled oil”) abroad, which allows them to be treated equivalently. -

interviewWeCharge: EV charging management system that can be operated in large parking areasEfforts intended to achieve carbon-neutral levels have been made increasingly more often, which requires expansion of the EV charging infrastructure in order to propagate electric vehicles (hereinafter called “EV”).

interviewWeCharge: EV charging management system that can be operated in large parking areasEfforts intended to achieve carbon-neutral levels have been made increasingly more often, which requires expansion of the EV charging infrastructure in order to propagate electric vehicles (hereinafter called “EV”).