Transformer Abnormality Diagnosis and Deterioration Diagnosis Technique Using Gas-in-Oil Sensors

- Kenji Ogawa

- Fumio Kurihara

With the rapid progress in the utilization of technologies such as IoT and AI, the technological development of electric power networks is progressing at a remarkable speed. However, many problems still remain in the power receiving and transforming equipment, and the smart maintenance is one of the important themes, especially for the high-age transformers that have been used for decades.

While the importance of maintenance of electric power infrastructure devices and the need for sophistication continue to grow, the current maintenance method is still an old-fashioned method of measuring and evaluating gas components in insulating oil taken from transformers. With this method, it was necessary to visit the site, bring back the sampled oil, and run it through an analyzer, which had the disadvantage of being laborious and time-consuming.

In order to make maintenance more efficient by utilizing digitization techniques such as IoT, AI in recent years, TAKAOKA TOKO is conducting research on smart transformers using gas-in-oil sensors and smart maintenance. We will introduce a technology that simultaneously performs transformer abnormality diagnosis and deterioration diagnosis by continuously measuring gas in oil, oil temperature, and water in oil.

Technology

Development of transformer condition diagnosis technology based on constant monitoring that realizes smart maintenance.

It is reported that the number of aging transformers has been increasing over the years in Japan, and that the number of 30-year-old transformers is increasing at a pace of 100 units per year. As the insulation paper inside the transformer deteriorates, the risk of winding insulation breakdown increases in the event of an accident such as an external short circuit. However, the maintenance to avoid the risk has a problem of a large cost in terms of man-hours and money. TAKAOKA TOKO has therefore developed a new transformer condition diagnosis technology that makes maintenance more efficient.

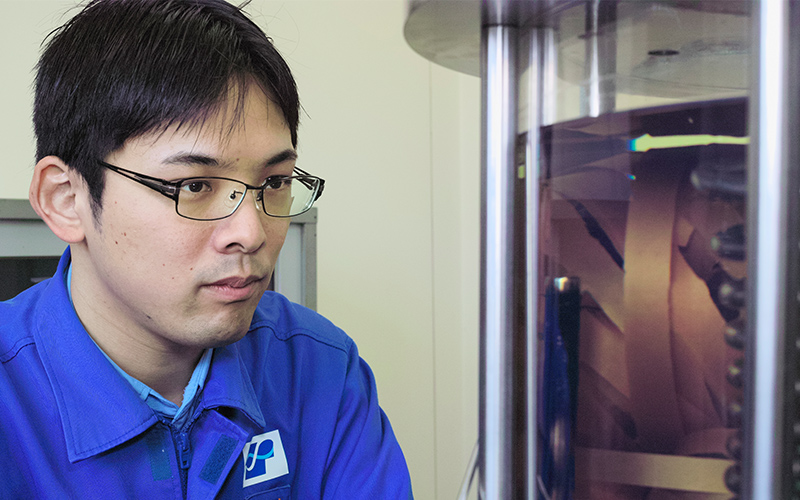

Until now, we checked the deterioration products by running the sampled insulating oil through an analyzer to determine the condition of the transformer. TAKAOKA TOKO noticed that the water balance relationship*1 between insulating paper and insulating oil changes in response to the deterioration of insulating paper, and decided to continuously measure gas-in-oil, oil temperature, and water-in-oil by using gas-in-oil sensors in the verification device, and analyze the changes. As a result, we have succeeded in reproducing the abnormality and deterioration diagnosis inside the transformer due to numerical changes in the physical properties of each of them within the verification device. Therefore, we are working to solve practical problems and improve accuracy in order to realize practical operations in actual devices as soon as possible.

*1) In oil, water in paper elutes into oil due to the effect of temperature, and the concentration equilibrium between water content in paper and water content in oil is maintained.

Profile

-

Kenji OgawaTechnology Development Division

Kenji OgawaTechnology Development Division

Research and Development Center

Materials Technology Group

(at the time of development) -

Fumio KuriharaTechnology Development Division

Fumio KuriharaTechnology Development Division

Research and Development Center

Materials Technology Group Manager

and General Manager of Material Technology Dept.

By focusing on physical phenomena associated with deterioration, we have developed a new diagnostic technology.

Kurihara:In 2016, we actually began in-house study of degradation diagnostics using gas-in-oil sensors. The maintenance by extracting oil and analyzing it is a heavy burden on the implementer. On the other hand, it is too expensive to install sensors for measuring degradation products. Then, we began to discuss whether it is possible to use sensors for measuring physical phenomena associated with deterioration rather than products.

Ogawa:The first thing we focused on was water. The water balance relationship, which indicates the water content of insulating paper and oil, changes according to the degree of deterioration of insulating paper and oil temperature. In other words, we thought that if the oil temperature and water content in the oil could be measured, the degree of deterioration of the insulating paper could be estimated. There are many sensors that can accurately measure oil temperature and water content in oil, so there is no need to develop a new sensor.

Kurihara:Attaching sensor enables continuous measurement, so data can be measured and analyzed continuously over time. In addition, in the past, maintenance was performed only once every few years, and status diagnosis could only be performed at that timing. With this method, however, changes in transformer status can be grasped in real time. This makes it possible to catch signs of serious deterioration and associated abnormalities before they occur, enabling timely device replacement.

Ogawa:The advantages are not only that. By connecting the sensor to the network and uploading the measurement data to the cloud, it is possible to check it remotely. If it is possible to analyze the accumulated data in cooperation with AI, the range of utilization should expand, including further improvements in accuracy.

Kurihara:In addition, early detection of deterioration leads to replacement of old transformers. The expected life of a transformer is said to be about 30 years, but some transformers are used for a longer time. Despite the fact that the risk of failure of transformers increases as they deteriorate over time, deterioration cannot be distinguished unless maintenance is performed. If the status can be monitored by the sensor, it may be possible to determine a more appropriate replacement time.

Ogawa:That is, if this technology is put into practical use, it can realize many advantages such as reduction of maintenance man-hours and cost savings, appropriate device operation, remote checking on the cloud, and AI linkage. It not only can make the operation of power receiving and transforming equipment more efficient, but also can contribute to their stability. This is the transformer condition diagnosis technology that we are researching using gas-in-oil sensors.

In order to contribute to the efficiency of operation, we aim to put it into practical use as soon as possible.

Kurihara:The early stages of development went surprisingly smoothly. The oil temperature of the transformer rises as time passes from operation. If the load factor decreases from the evening to the night, the oil temperature also decreases. We thought that the amount of water in the oil should change with a slight delay from the change in oil temperature. The movement of the actually measured numerical value is also as expected. We became more confident in our hypotheses.

Ogawa:However, a wall was waiting in the next stage. That is the water content adjustment of the insulating paper. As the next step in measuring the change in water content due to oil temperature change, it is necessary to measure how the water content changes depending on the degree of deterioration of paper. For this reason, it is necessary to deteriorate the paper. However, it was difficult to adjust the water content to match the target degree of deterioration with accuracy, and we had a hard time to do so.

Kurihara:Unless the conditions are met, accurate verification results cannot be obtained. It is therefore necessary to adjust not only the degree of deterioration, but also the amount of water in each piece of paper with a different degree of deterioration. In order to release only the targeted amount of water from the paper, we have prepared the verification conditions while carefully adjusting the oil temperature and time.

Ogawa:We finally got to the verification, but when we checked the verification results, we found a new problem. Although it was possible to confirm the presence or absence of deterioration, it was not possible to determine the degree of deterioration. Therefore, instead of using the movement of the water content as an index, we came up with an evaluation of the degree of deterioration based on the integrated value of the amount of water movement.

Kurihara:Our idea is as follows: The real-time movement of water content due to oil temperature change is very small based on the degree of deterioration, but by integrating the difference by one day, it is calculated as a larger difference, and the degree of deterioration is measured from the magnitude of the difference. As a result of actual verification, we were able to measure the degree of deterioration using this method. Although it is not yet accurate enough to be commercialized, we have found a clue to a major solution.

Ogawa:We have succeeded in verifying deterioration diagnosis based on the amount of water in oil, which was our original objective, and are currently proceeding with research and development aimed at practical application. There are still many problems to be addressed by the time of the operation. The oil retention problem is one of them. Since the installation position to the transformer was assumed to be the oil drain valve, oil remained in the volume from the oil drain valve to the sensor installation adapter, and the oil temperature change could not be measured accurately. However, we are currently trying to solve this problem. While there are still barriers to overcome, such as improving the accuracy and quantifying the degree of deterioration, we are aiming for putting the technology into practical application as soon as possible in order to contribute not only to Japan but also to improving the efficiency of the operation of power receiving and transforming equipment worldwide.

Latest articles

-

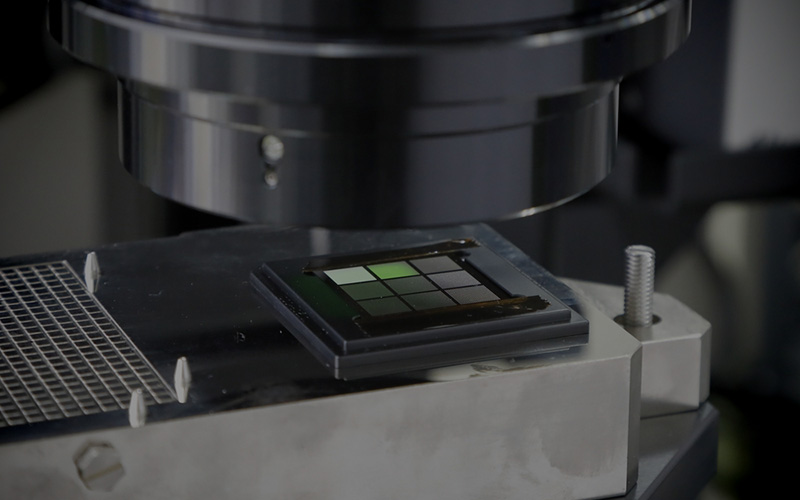

interviewThe confocal surface shape measurement system for semiconductor reliabilityIt is no exaggeration to say that semiconductors are used in everything supporting our lives and industry in modern society. Examples include smartphones, home appliances, and industrial products in various fields.

interviewThe confocal surface shape measurement system for semiconductor reliabilityIt is no exaggeration to say that semiconductors are used in everything supporting our lives and industry in modern society. Examples include smartphones, home appliances, and industrial products in various fields. -

interviewImplementation of a Sensor Solution for Substation DigitalizationGlobal energy prices remain at high levels. The presumed cause is the imbalance between energy supply and demand due to recovery in economic activity from the spread of COVID-19, unseasonable weather, disasters, Russia's invasion of Ukraine, and other factors. The soaring energy prices naturally have an impact on the electricity sector, putting not only ordinary households but also electricity suppliers, or electric power companies, in a difficult situation. Power companies are being forced to cut costs to keep power prices down.

interviewImplementation of a Sensor Solution for Substation DigitalizationGlobal energy prices remain at high levels. The presumed cause is the imbalance between energy supply and demand due to recovery in economic activity from the spread of COVID-19, unseasonable weather, disasters, Russia's invasion of Ukraine, and other factors. The soaring energy prices naturally have an impact on the electricity sector, putting not only ordinary households but also electricity suppliers, or electric power companies, in a difficult situation. Power companies are being forced to cut costs to keep power prices down. -

interviewDevelopment of Techniques for Solar Power Generation Prediction Using AIIn order to promote carbon neutrality, the use of renewable energy that doesn't emit CO2 is expanding.Among renewable energy resources, solar power generation is an important one which will continue to grow in popularity.

interviewDevelopment of Techniques for Solar Power Generation Prediction Using AIIn order to promote carbon neutrality, the use of renewable energy that doesn't emit CO2 is expanding.Among renewable energy resources, solar power generation is an important one which will continue to grow in popularity. -

interviewDevelopment of Medium-Capacity Quick Charger for Electric VehiclesIn anticipation of expansion of EV charging infrastructure in Japan, where the EV shift is accelerating, we worked on the development of the “medium-capacity quick charger (B11)” as a charger that meets the needs for intermediate chargers between normal chargers and quick chargers. This article introduces the features of the product, ingenuity in the development process, and our future vision.

interviewDevelopment of Medium-Capacity Quick Charger for Electric VehiclesIn anticipation of expansion of EV charging infrastructure in Japan, where the EV shift is accelerating, we worked on the development of the “medium-capacity quick charger (B11)” as a charger that meets the needs for intermediate chargers between normal chargers and quick chargers. This article introduces the features of the product, ingenuity in the development process, and our future vision.