Clarification of Earthquake Damage Mechanism for Earthquake Resistance Improvement of Disconnector

- Tomoyuki Ohyama

- Kazuhiko Kanda

- Kiyoshi Nagata

In Japan, a country prone to earthquakes, high earthquake resistance is required for power devices. In recent years, in the 2011 off the Pacific coast of Tohoku Earthquake and Kumamoto earthquake, the largest seismic motions in recorded history were observed in quick succession, greatly exceeding the seismic design regulations for transforming devices. Since the earthquake-induced damage to substations and other power devices responsible for the power infrastructure has a significant impact on the power system, we are reviewing the seismic design and considering further improvements in seismic performance.

In fact, disconnectors*1 were severely damaged in the 2011 off the Pacific coast of Tohoku Earthquake. Therefore, TAKAOKA TOKO conducted various verification experiments and seismic analysis in order to clarify the mechanism of disconnector damage caused by the same earthquake. We have succeeded in developing a damper that significantly improved the seismic performance of the disconnector and could withstand huge earthquakes observed both domestically and overseas. Here we introduce new technologies that protect disconnectors from future large-scale earthquakes and contribute to a stable power supply.

*1) Switches used in high-voltage electrical circuits.

Technology

Development of a damper with improved earthquake resistance that can withstand a huge earthquake by exploring the damage mechanism.

On March 11, 2011, the Pacific coast of Tohoku Earthquake, the largest earthquake ever observed, occurred. The damage was serious, and the power infrastructure including substations suffered serious damage. Japan is one of the most earthquake-prone countries in the world, and power devices have improved their earthquake resistance through repeated earthquake damage. Seismic resistance improvement measures have also been adopted for disconnectors, such as installing moving parts that serve as seismic isolation devices in insulator*2 devices. However, the magnitude of the 2011 off the Pacific coast of Tohoku Earthquake was far higher than expected.

As a result, a large number of disconnectors were damaged. Therefore, TAKAOKA TOKO set out to clarify the damaged parts and the damage mechanism. While conducting computer simulations and reproduction experiments of damage phenomena, we clarified the phenomenon and developed a new friction damper that can withstand a megathrust earthquake of the the Pacific coast of Tohoku Earthquake class. By using a ring spring for the damper, we have succeeded in miniaturizing it so that it can be installed on existing machines while ensuring sufficient damping force. It has already been delivered to TEPCO (Tokyo Electric Power Co.). In the future, we will proceed with the study of devices with even higher vibration suppression effects, and proceed with research toward the development of products that can be installed easily.

*2) Instrument used for insulation

Profile

-

Tomoyuki OhyamaPower Equipment & System Business Division

Tomoyuki OhyamaPower Equipment & System Business Division

Disconnector manufacturing department

Design group

Chief -

Kazuhiko KandaTechnology Development Division

Kazuhiko KandaTechnology Development Division

Research and Development Center

Computer Analysis & High Power Testing Group

Deputy section manager -

Kiyoshi NagataPower Equipment & System Business Division

Kiyoshi NagataPower Equipment & System Business Division

Disconnector manufacturing department

Design group

Manager of switch technology section

Surprising results shown by experiments with seismic waves observed in Fukushima.

Nagata:On March 11, 2011, the disconnector was also damaged by the 2011 off the Pacific coast of Tohoku Earthquake. It all starts here. At the time, I was working at the Tochigi office, and I knew that the scale of the earthquake was so large that damage to the local disconnector would be inevitable. As a result, the earthquake greatly exceeded the seismic design regulations for substation devices, and even in the case of TEPCO's 550kV disconnector having high seismic resistance, the actual number of damages and the aspect of damages far exceeded our expectations. From the point that we had to do something about this, we launched a project to improve earthquake resistance.

Kanda:Until now, 550kV disconnector has been equipped with a movable part, which is a seismic isolation device, on the insulator device as a measure for improving seismic resistance. However, the earthquake on March 11 was so massive that it exceeded the assumption of a seismic isolation device, leading to severe damage.

Nagata:Immediately after the earthquake, TEPCO, to which we delivered our disconnectors, requested us to propose countermeasures. In the beginning, our proposal was simple and to "increase the strength by applying high-strength insulators and increasing the thickness of insulators." However, the technical team of TEPCO at the time said, "Let's thoroughly investigate the cause and then pursue essential earthquake resistance measures."

Ohyama:It was exactly as they said, and we had no words to reply. If the countermeasures were to be taken as we proposed, all insulators would need to be completely replaced, and the cost would be enormous. It was not an appropriate measure. So we began again by clarifying the damaged parts and the damaged mechanism. We immediately collected damaged insulators and seismic isolators and examined them. We found that the parts of the seismic isolators had collided violently. Therefore, we hypothesized that the insulators might be damaged due to the violent collision of the parts of the seismic isolation system with each other.

Kanda:According to our previous knowledge, the seismic isolation system that had been adopted was not resonating with the seismic motion of the ground in Japan, but we were able to clearly confirm traces of collisions between parts of the seismic isolation system. However, the movable range was also small for its structure, and it did not seem possible to generate impact force enough to break the insulator. Even though the seismic motion was larger than expected, we wondered whether an impact force really occurred and whether the impact force was strong enough to destroy the insulator in an instant. Although half in doubt, we conducted a computer simulation and an experiment to reproduce the phenomenon.

Kanda:The results of the seismic analysis, as well as the experimental results, were surprising. When we conducted a reproduction experiment using actually observed seismic waves, they were actually destroyed due to the impact. Since the tremors caused by the earthquake were so strong, the experiment preproduced how the parts of the seismic isolation system collided violently with each other, causing the breakage of insulators.

Ohyama:From there, we proceeded with detailed investigations into the causes of damage, including how the disconnector would respond to an earthquake and how large an impact would cause it to break. After receiving the relevant seismic waveform data from TEPCO, we repeatedly sophisticated the analysis model and repeated simulations. After spending more than half a year, we were finally able to identify the cause.

Further improvements in earthquake resistance and convenience with the aim of commercialization.

Nagata:We succeeded in simulating the impact phenomenon, and conducted experiments to get an idea of the impact force. The next challenge was how to reduce the impact force. Ultimately, we developed a friction damper that used a ring spring and attached it to the existing device. However, the road up to that point was not an easy one.

Kanda:The seismic analysis requires first creating an analysis model. Assembling a model itself is not that difficult, but it is very difficult to create a detailed analysis model while repeating fine adjustments so that it acts in the same way as the actual action. Since the accuracy and sophistication of this model greatly affect the accuracy of subsequent verification operations, we have focused on sophisticating the analysis model.

Nagata:As a result, we were able to create an analysis model with extremely high reproducibility, which could be said to be the highest level in Japan for earthquake resistance technology for substation devices. Currently, we are making proposals for improving earthquake resistance not only in Japan but also overseas. What ensures the persuasiveness of these proposals is our extensive experience in experiments and our elaborate analysis model.

Ohyama: In order not only to sophisticate the analysis model, but also to make sure that the data to be input into the model is perfect, we proceeded with data collection in cooperation with electric power companies and research institutes throughout Japan. In addition, since it would not be meaningful if new earthquake-resistant device could be developed but could not be installed in existing devices, we tried various types of springs while being conscious of fitting it within the space so that it can be installed in existing devices.

Nagata:Whether it could be installed in the existing device was a very important point. In Japan, it is difficult to imagine the construction of new 550kV class substations in the future, and it is rare to completely replace existing 550kV disconnectors. If we could not install it in existing device, there would be no way to put our developed technology into practical use. Therefore, we proceeded with development while always being conscious of practical application.

Ohyama: In this way, we were able to complete a friction damper for TEPCO. However, the road is still halfway. In the future, we would like to further improve the performance of this device and brush it up in consideration of the ease of installation for practical use.

Kanda:There have been new research results even since the countermeasures were taken against the 2011 off the Pacific coast of Tohoku earthquake. That is the Kumamoto Earthquake. Although the disconnector was also damaged in the same earthquake, we used the knowledge of seismic analysis technology cultivated in our research to identify the vibration direction with low seismic strength in the analysis model. In addition, we were able to derive measures to absorb the stress generated in a weak portion. We would like to respond to customer needs by making use of the knowledge obtained through this research and development, as in these examples.

Latest articles

-

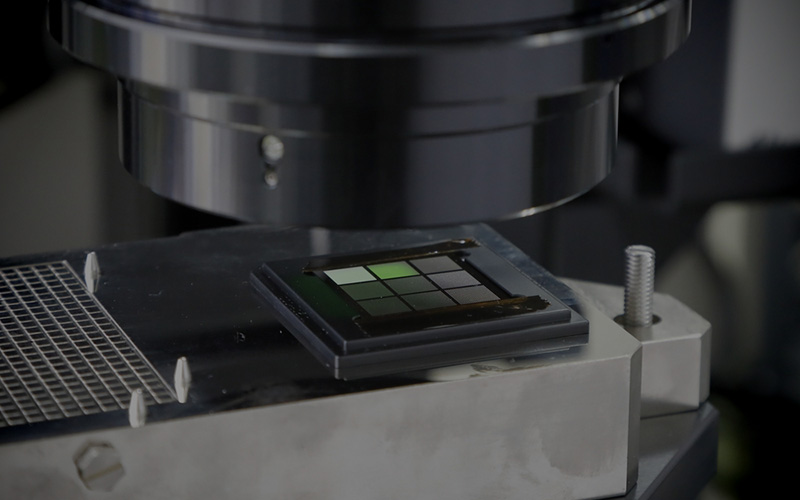

interviewThe confocal surface shape measurement system for semiconductor reliabilityIt is no exaggeration to say that semiconductors are used in everything supporting our lives and industry in modern society. Examples include smartphones, home appliances, and industrial products in various fields.

interviewThe confocal surface shape measurement system for semiconductor reliabilityIt is no exaggeration to say that semiconductors are used in everything supporting our lives and industry in modern society. Examples include smartphones, home appliances, and industrial products in various fields. -

interviewImplementation of a Sensor Solution for Substation DigitalizationGlobal energy prices remain at high levels. The presumed cause is the imbalance between energy supply and demand due to recovery in economic activity from the spread of COVID-19, unseasonable weather, disasters, Russia's invasion of Ukraine, and other factors. The soaring energy prices naturally have an impact on the electricity sector, putting not only ordinary households but also electricity suppliers, or electric power companies, in a difficult situation. Power companies are being forced to cut costs to keep power prices down.

interviewImplementation of a Sensor Solution for Substation DigitalizationGlobal energy prices remain at high levels. The presumed cause is the imbalance between energy supply and demand due to recovery in economic activity from the spread of COVID-19, unseasonable weather, disasters, Russia's invasion of Ukraine, and other factors. The soaring energy prices naturally have an impact on the electricity sector, putting not only ordinary households but also electricity suppliers, or electric power companies, in a difficult situation. Power companies are being forced to cut costs to keep power prices down. -

interviewDevelopment of Techniques for Solar Power Generation Prediction Using AIIn order to promote carbon neutrality, the use of renewable energy that doesn't emit CO2 is expanding.Among renewable energy resources, solar power generation is an important one which will continue to grow in popularity.

interviewDevelopment of Techniques for Solar Power Generation Prediction Using AIIn order to promote carbon neutrality, the use of renewable energy that doesn't emit CO2 is expanding.Among renewable energy resources, solar power generation is an important one which will continue to grow in popularity. -

interviewDevelopment of Medium-Capacity Quick Charger for Electric VehiclesIn anticipation of expansion of EV charging infrastructure in Japan, where the EV shift is accelerating, we worked on the development of the “medium-capacity quick charger (B11)” as a charger that meets the needs for intermediate chargers between normal chargers and quick chargers. This article introduces the features of the product, ingenuity in the development process, and our future vision.

interviewDevelopment of Medium-Capacity Quick Charger for Electric VehiclesIn anticipation of expansion of EV charging infrastructure in Japan, where the EV shift is accelerating, we worked on the development of the “medium-capacity quick charger (B11)” as a charger that meets the needs for intermediate chargers between normal chargers and quick chargers. This article introduces the features of the product, ingenuity in the development process, and our future vision.