Developing a multi-terminal transmission-type OLR device that realizes optimum transmission line overload control

- Ryusuke Takahata

- Hidekazu Tanuma

Intelligent electronic devices (IEDs) that incorporate computing technology for monitoring and controlling various devices used in electric power equipment are being introduced. In particular, in Europe, the United States, and emerging countries where the development of electric power infrastructure has been delayed, digital substations are increasingly being introduced, which digitize all the monitoring and control of power equipment at substations by utilizing the International Standards IEC 61850 and interconnecting multiple IEDs through network, regardless of differences between vendors.

Since Japan already possesses its own electric power equipment with unique security and high supply reliability, and the necessity of introducing digital substations was low, it became a Countries lagging behind in digitization worldwide. However, since many existing equipment and facilities are now in the replacement period, we are trying to shift to digitization.

With the conversion to renewable energy sources being promoted to realize a decarbonized society, the problem is how to efficiently control the power supply by photovoltaic power generation, etc., which is easily affected by the natural environment, and the digitalization of the power infrastructure will lead to a point for solving this problem.

Under such circumstances, TAKAOKA TOKO is the first in Japan to develop a "Multi-terminal transmission type OLR (Over Load Relay) device" that optimizes transmission line overload control in compliance with the international standard IEC 61850.

Technology

As the introduction of renewable energy expands, it is necessary to control the overload of transmission lines that occur in response to the outage of transmission lines in the event of an accident, taking into consideration the fact that the amount of power generated by solar and wind fluctuates depending on the weather. When the conventional transmission line overload protection relay device is applied to solar power generation or wind power generation, unlike the application to relatively stable power generation methods such as thermal power generation, the load situation is difficult to grasp and control becomes difficult. The fact that power transmission lines are overloaded is rare, but in the unlikely event of an overload due to a power transmission line accident, a large-scale power outage may occur.

In the environment of the new era where renewable energy is spreading and expanding, "multi-terminal transmission type OLR device" has been developed as a device that suppresses and controls overloads caused by power line accidents.

This device is equipped with a general-purpose IED manufactured by SEL that conforms to the International Standard IEC 61850.

The development was also done in compliance with the same standard, and it was given interconnectivity that can provide a connection with other manufacturers via the network. In addition, the Power Equipment System Manufacturing Department is actively working on digital substations utilizing the International Standard IEC 61850, but the department uses the knowhow of the International Standard IEC 61850 that complies with the "Multi-Terminal Transmission OLR Device."

Profile

-

Ryusuke TakahataPower Equipment & System Business Division

Ryusuke TakahataPower Equipment & System Business Division

Power Equipment System Manufacturing Department

General Manager, Engineering Department -

Hidekazu TanumaPower Equipment & System Business Division

Hidekazu TanumaPower Equipment & System Business Division

Power Equipment System Manufacturing Department

Protection & Control Equipment Design Group

Overload control system for transmission lines for the age of renewable energy

Tanuma:The newly developed multi-terminal transmission type OLR device is intended for use in 66kV extra-high-voltage transmission lines. The 66kV transmission line is a thick transmission line stretched over transmission towers, etc. you may have seen it in urban areas. Normally, only half or less of the maximum transmission capacity flows through this transmission line. This means, for example, that if two lines are used for transmission, and one of them becomes unusable due to an accident such as a lightning strike somewhere, the remaining one line is used for the transmission for two lines.

Then, if the amount of power generated by the solar panel is at its maximum, the transmission line will become overloaded due to overcapacity. The role of this device is to detect this overload condition and, if necessary, cut off the power generation equipment to eliminate the overload condition and prevent the spread of accidents due to equipment damage on healthy lines, etc. The government is also trying to promote renewable energy, but renewable energy, whether it is wind power, water power, or solar power, has factors that make power output susceptible to fluctuations.

It is difficult to read the situation because the amount of power generation changes due to the natural environment. In addition, transmission capacity varies depending on the section. For example, there are cases where mega-solar power plants are built on sites that used to be golf courses, but such places are often rural, so they don't need much electricity.

This means that power is transmitted to urban areas. However, in the case of solar power generation, where the amount of supply is unstable, the current flowing through the transmission line varies depending on the location. Therefore, the detection of overload equipment (transmission line sections) due to accidents is more difficult than before unless the load condition is always grasped in detail. To solve this problem, the multi-terminal transmission OLR unit has incorporated a mechanism that allows detailed monitoring of how much power is flowing through the transmission line from the terminal device installed in each section of the transmission line to the central unit of the substation, and also sends a shut-off command to the terminal device in the overload section to shut off the power generation equipment in the event of an overload.

Takahata:It may be a rare case that one side of a two-circuit transmission line becomes unusable and one side becomes overloaded. However, if an equipment accident occurs due to overloading, chain reactions can occur, leading to large-scale power outages.

The major role of this device is to keep the damage caused by an accident as small as possible. This device also has the advantage of being able to grasp the situation of each section of the transmission line in detail, so that the power transmission capacity can be used without waste.

Compliance with the International Standard IEC61850

High versatility and cost advantage as well

Takahata:This time, the communication protocol between devices is designed to conform to the International Standard IEC 61850. This international standard presents the concept of the data structure of information exchanged in communication rather than the specification of the communication protocol, and implements the concept by mapping the concept to multiple existing communication protocols.

For example, the measurement data of the terminal device is sent this time to the central device by the communication protocol called MMS. However, when sending the shutdown signal from the central device, a communication protocol called GOOSE, which has a quick response is used. In other words, you can choose the protocol that suits your purpose.

In this case, what is specified in IEC 61850 means that the content of information to be exchanged is specified. Specifically, by defining the function and structure of the data to be exchanged, including the name of the data, it is possible to make connections even by using devices manufactured by different manufacturers as long as they comply with the standards.

In the past, different manufacturers had different definitions of data functions and structures, making interconnection between different manufacturers difficult. But using IEC 61850 makes it easier.

In addition, by using international general-purpose products from other companies that comply with this standard, the development period of a system can be shortened and costs can be reduced.

In May 2017, TAKAOKA TOKO began developing a transmission line overload protection relay system using the international standard protocol, and adopted the international standard for the information transmission of protection relays.

In August 2019, we also began developing a substation remote monitoring and control system for power distribution that conforms to the International Standard IEC 61850 for substation monitoring and control information. Furthermore, in March 2020, we built a monitoring and control system for digital substations by combining international general-purpose products in a network that complies with international standards.

We will continue to actively utilize international standards for monitoring and control systems.

In Conclusion - Aiming to Build Power Infrastructure for the New Era

Nowadays, most people use cloud services when using computers at work, when enjoying music and video distribution on smartphones, and when making cashless payments.

While these services are supported by datacenter servers, the power they use is very large and requires a stable "non-stop" power supply.

As automobiles become more electrified, there is also a rapid rise in demand for electricity as a means of powering vehicles.

While promoting the use of renewable energy with the aim of decarbonization, there is a need to further enhance the efficiency and safety of electric power supply.

TAKAOKA TOKO will continue to work on building the power infrastructure of the new era through compliance with international standards and integration through digitalization of power equipment.

Latest articles

-

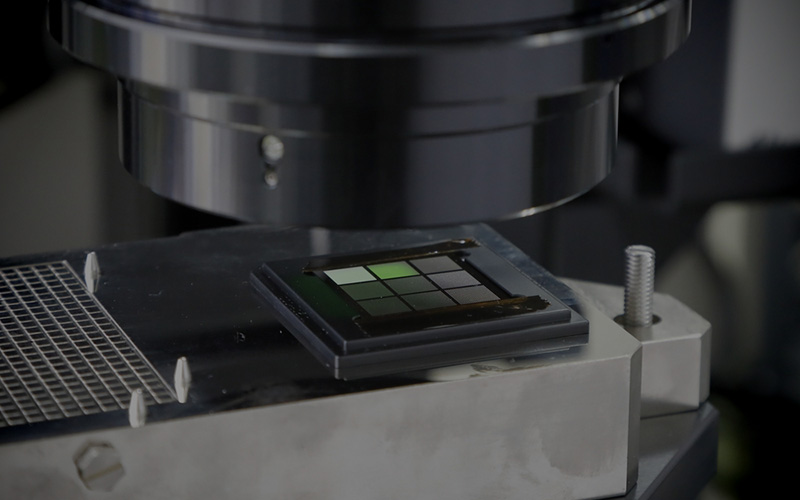

interviewThe confocal surface shape measurement system for semiconductor reliabilityIt is no exaggeration to say that semiconductors are used in everything supporting our lives and industry in modern society. Examples include smartphones, home appliances, and industrial products in various fields.

interviewThe confocal surface shape measurement system for semiconductor reliabilityIt is no exaggeration to say that semiconductors are used in everything supporting our lives and industry in modern society. Examples include smartphones, home appliances, and industrial products in various fields. -

interviewImplementation of a Sensor Solution for Substation DigitalizationGlobal energy prices remain at high levels. The presumed cause is the imbalance between energy supply and demand due to recovery in economic activity from the spread of COVID-19, unseasonable weather, disasters, Russia's invasion of Ukraine, and other factors. The soaring energy prices naturally have an impact on the electricity sector, putting not only ordinary households but also electricity suppliers, or electric power companies, in a difficult situation. Power companies are being forced to cut costs to keep power prices down.

interviewImplementation of a Sensor Solution for Substation DigitalizationGlobal energy prices remain at high levels. The presumed cause is the imbalance between energy supply and demand due to recovery in economic activity from the spread of COVID-19, unseasonable weather, disasters, Russia's invasion of Ukraine, and other factors. The soaring energy prices naturally have an impact on the electricity sector, putting not only ordinary households but also electricity suppliers, or electric power companies, in a difficult situation. Power companies are being forced to cut costs to keep power prices down. -

interviewDevelopment of Techniques for Solar Power Generation Prediction Using AIIn order to promote carbon neutrality, the use of renewable energy that doesn't emit CO2 is expanding.Among renewable energy resources, solar power generation is an important one which will continue to grow in popularity.

interviewDevelopment of Techniques for Solar Power Generation Prediction Using AIIn order to promote carbon neutrality, the use of renewable energy that doesn't emit CO2 is expanding.Among renewable energy resources, solar power generation is an important one which will continue to grow in popularity. -

interviewDevelopment of Medium-Capacity Quick Charger for Electric VehiclesIn anticipation of expansion of EV charging infrastructure in Japan, where the EV shift is accelerating, we worked on the development of the “medium-capacity quick charger (B11)” as a charger that meets the needs for intermediate chargers between normal chargers and quick chargers. This article introduces the features of the product, ingenuity in the development process, and our future vision.

interviewDevelopment of Medium-Capacity Quick Charger for Electric VehiclesIn anticipation of expansion of EV charging infrastructure in Japan, where the EV shift is accelerating, we worked on the development of the “medium-capacity quick charger (B11)” as a charger that meets the needs for intermediate chargers between normal chargers and quick chargers. This article introduces the features of the product, ingenuity in the development process, and our future vision.