Development of a fault section detection system that enables rapid power restoration

- Yoichi Naraki

- Yuki Shiino

Electricity is essential in our lives. A number of substations through which electricity is provided from a power station to houses have a key role in the stable delivery of power.

The substation facilities consist of not only a transformer and breaker, but also the wires (overhead lines) connecting them in a circuit. If an accident, such as lightning, involves the overhead line, power fails across a wide area that receives that power from the substation. Therefore, it is necessary to quickly detect an accident and promptly restore the power. Since many substations are unattended, however, the first step is for a device to detect the fault section due to the accident so that automatic recovery can be initiated. The fault section detection system is one of the devices that play such a role.

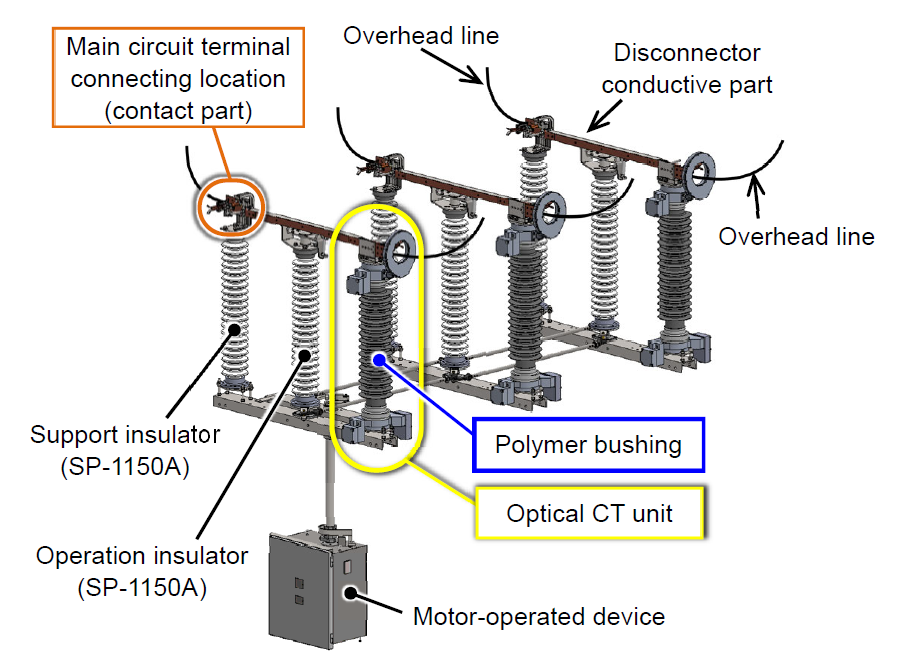

Takaoka Toko developed a fault section detection system consisting of a new air disconnector (hereinafter referred to as the “new disconnector”) with an optical current sensor (hereinafter referred to as the “optical CT”) that can detect current during an accident and is mounted on a polymer bushing with built-in optical fiber and a detection device miniaturized more significantly than conventional products.

Technology

New fault section detection system resistant to salt damage and earthquakes

The fault section detection system currently developed consists of a new disconnector combining the polymer bushing containing the optical fiber with the optical CT, a detection panel, and optical fiber cables connecting them.

For a new disconnector, we adopted the polymer bushing made by RPC* with technology wherein the optical fiber is combined with a bushing. The problem in response to a very heavy pollution area containing a large amount of salt in the air, such as a coast district, was that the creepage distance of conventional porcelain bushings is short. Since the polymer is likely to be shaped in comparison to the porcelain, a polymer bushing of the same size as the conventional porcelain bushing with a high resistance to salt (having a long creepage distance) can be made. For the new disconnector, we chose a polymer bushing that is highly resistant to salt and designed for delivery even to very heavy pollution areas. In addition, since the optical CT installed on the upper part of the polymer bushing is likely to be affected by tremors from an earthquake, the body diameter of the polymer bushing is increased to cope with that problem.

The detection panel based on our company’s conventional product is miniaturized for installation even in limited spaces. We choose cabinet type for housing, and the device error LED and the control power LED mounted on the front door of the housing allows the operating status to be viewed without opening the door.

*Abbreviation of Reinhausen Power Composites GmbH. A manufacturer of high-voltage composite insulators in Germany.

Profile

-

Yoichi NarakiPower Equipment & System Business Division

Yoichi NarakiPower Equipment & System Business Division

Engineering DepartmentⅡ

Protection & Control Equipment Design Group -

Yuki ShiinoPower Equipment & System Business Division

Yuki ShiinoPower Equipment & System Business Division

Engineering DepartmentⅡ

Protection & Control Equipment Design Group

Development of new devices by taking advantage of accumulated experience

NarakiIf an accident occurs in the overhead line of a substation, power fails in all areas covered by the substation. Since substations are often unattended, the fault section of the overhead line must be located using a device first. The fault section detection system is one of the devices that play such a role. The purpose of the device is to promptly restore power after a failure due to an accident by quickly detecting the fault section.

As a fault section detection system, we previously adopted a disconnector with an optical CT using a porcelain bushing but never used a polymer bushing. Therefore, we promoted the new development this time.

ShiinoThe device referred to as the disconnector does not usually have an optical CT. However, incorporating the optical CT into the disconnector will save the effort of separate installation of a sensor in a high place with the overhead line that detects the current during an accident. Some manufacturers dealt with similar products in the past. Today, we are the only manufacturer that developed and commercialized the device of a disconnector combined with an optical CT.

NarakiSince I was engaged in a similar item before development of this device, I was in charge of consideration of the overall specifications of the device, development of the detection panel, and the organization of the whole development. The detection panel is decreased in size in comparison to conventional products for installation in the limited space of a building.

Since delivery time to the substation was determined and the development period was limited, I paid close attention to schedule management in particular. Review and correction were required as we worked, so I felt pressure for schedule management from the position of the organizer for the whole process.

ShiinoSince joining the company, I have been involved with optical CT for many years, and as a result, I was put in charge of developing sensors for the detection panels. For miniaturization of the detection panel, I reviewed the wiring of the optical cables in the panel, and I prepared the instruction manual for the installation method and the operation method for the panel.

Since the detection panels were always large up to now, our company staff needed to install them on-site. However, they are now miniaturized, which allows customers to install them. Therefore, I prepared the documents, including the instruction manual, in greater detail for easy understanding.

Challenge with fellows having different experiences at different departments to make a better product

NarakiIn the development test, we check many items to confirm whether official standards and the customers’ own standards are met. For the current development, it was necessary to conduct tests that were not defined by the standards of the customers with whom I had been involved before. In previous tests, should they fail, it was easy to anticipate the cause or the measures we needed to implement based on experience. However, that would be difficult for a test that had not been conducted before. Actually, in the first test, the standard value was exceeded, which was handled by trial and error, such as replacing the part with one borrowed from an external test station and using information from experts. There were many things we did not understand, which caused difficulties.

ShiinoIn the part for which I was responsible, the wiring in the detection panel was difficult. In the miniaturized detection panel, we had to accommodate the necessary components and wiring in less space than before. In particular, the components must be compacted with careful attention to avoid breaking them since the optical cables have an internal glass structure and cannot be bent sharply. Therefore, I determined the wiring by trying a prototype in different ways. Moreover, to confirm whether there was a problem with assembly and workability, I obtained feedback from the relevant parties and from different viewpoints in order to make the corrections. I succeeded in accommodating them one way or another by figuring out the orientation of members and the position of the wiring.

NarakiWe all fully discussed and worked well together, including other members.

Shiino Since a plurality of departments within the company were involved in the fault section detection system, I interacted with the other departments, including the disconnector department. Furthermore, in the step of preparing the instruction manual, I requested that a person with less experience in operating the detecting panel do so while using the operation manual, and I obtained feedback from that person. It was good to have corrected the portions that were not noticed by those of us familiar with the operation.

Pleasure of completion, proceeding to the next development

NarakiI feel a good about the fact that the device is nicely integrated while meeting the standards and specifications planned in the early phase of development. When I saw that the first product was being shipped by truck, I thought we made it with a deep feeling. I expect the fault section detection system developed at this time will be a new standard model to be delivered. I would like to apply the new experience and knowledge obtained in the development to the development of other devices.

Shiino It was difficult to promote the development in the limited schedule, but I succeeded in meeting the standards and specifications, and I am relieved that the device is being operated safely on-site. Since introduction of the 3D CAD facilitated consideration of the device, I would like to make the most of it for other developments in the future. In addition, I acquired extensive knowledge on the wiring method and member layout in a limited space and on the heat trapped under such conditions, and I would like to make use of the learning from the experience in the future.

Latest articles

-

interviewDevelopment of a fault section detection system that enables rapid power restorationElectricity is essential in our lives. A number of substations through which electricity is provided from a power station to houses have a key role in the stable delivery of power.

interviewDevelopment of a fault section detection system that enables rapid power restorationElectricity is essential in our lives. A number of substations through which electricity is provided from a power station to houses have a key role in the stable delivery of power. -

interviewPowerFactory—analytic technology underpinning the stable supply of electric powerIn Japan, the retail business of electric power became fully liberalized in 2016. Retail operators not only sell electricity but must also balance demand and supply as they relate to the electric power system (electric power grid from the power plant to the delivery of electricity to customers) to enable customers to reliably use electricity. In addition, renewable energy continues to be introduced through efforts to become carbon neutral by 2050, which is making it more difficult to maintain a balance between demand and supply. Thus, the need to engage in visualization to ascertain the flow of electricity through an electric power system is growing. Consequently, analytic software for electric power systems will play a role.

interviewPowerFactory—analytic technology underpinning the stable supply of electric powerIn Japan, the retail business of electric power became fully liberalized in 2016. Retail operators not only sell electricity but must also balance demand and supply as they relate to the electric power system (electric power grid from the power plant to the delivery of electricity to customers) to enable customers to reliably use electricity. In addition, renewable energy continues to be introduced through efforts to become carbon neutral by 2050, which is making it more difficult to maintain a balance between demand and supply. Thus, the need to engage in visualization to ascertain the flow of electricity through an electric power system is growing. Consequently, analytic software for electric power systems will play a role. -

interviewEV charging in the interval between errands. aima CHARGEWith the aim of carbon neutrality, Japan set the goal to achieve 100 percent electrified vehicles in new passenger car sales by 2035. The proliferation and expansion of the EV charging infrastructure is essential for the proliferation of electric vehicles (hereinafter referred to as “EV”), and the Ministry of Economy, Trade and Industry set the goal of building 300,000 EV charging equipment by 2030.

interviewEV charging in the interval between errands. aima CHARGEWith the aim of carbon neutrality, Japan set the goal to achieve 100 percent electrified vehicles in new passenger car sales by 2035. The proliferation and expansion of the EV charging infrastructure is essential for the proliferation of electric vehicles (hereinafter referred to as “EV”), and the Ministry of Economy, Trade and Industry set the goal of building 300,000 EV charging equipment by 2030. -

interviewProposal for new value via the first steel-tower-type full-color rendering illumination in JapanSince July in 2021, Prifoods Stadium in Hachinohe City, Aomori Prefecture has operated LED illumination equipment capable of the first steel-tower-type full-color light rendering in Japan. Takaoka Toko/Kyoya Denki/CADEC specific construction work consortium accepted an order for this equipment from Hachinohe City, and it was completed after nine months of work.

interviewProposal for new value via the first steel-tower-type full-color rendering illumination in JapanSince July in 2021, Prifoods Stadium in Hachinohe City, Aomori Prefecture has operated LED illumination equipment capable of the first steel-tower-type full-color light rendering in Japan. Takaoka Toko/Kyoya Denki/CADEC specific construction work consortium accepted an order for this equipment from Hachinohe City, and it was completed after nine months of work.