Recycling technology of transformer oil aiming to achieve carbon neutrality

- Eriko Kitamura

- Mika Otake

Nowadays, the work involved in carbon neutrality and the establishment of a recycling society is essential in business activities. The same trend is observed in the field of transformer oil. The international standard for the quality of transformer oil has been revised; there is now no distinction in quality between new transformer oil and recycled transformer oil (hereinafter “recycled oil”) abroad, which allows them to be treated equivalently.

On the other hand in Japan, PCBs (polychlorinated biphenyls), which are hazardous to humans and the environment, were detected in recycled oil in the past, so used transformer oil is not use as transformer oil again now.

However, in consideration of the worldwide trend for environmental consciousness, the recycling of transformer oil will spread widely in Japan. Based on that background, our company is pursuing research in the recycling treatment of the used transformer oil. Here we will introduce our efforts.

Technology

Aiming to realize recycling of used transformer oil

Methods for recycling used transformer oil include the removal of impurities (e.g., filtration method); removal of dissolved degradation products existing in the transformer oil (e.g., adsorption method), and refining transformer oil through a chemical reaction (e.g., hydrotreatment method). Among those processes, we focused on the adsorption method by which recovery and improvement can be performed to a level that meets the quality requirements for transformer oil characteristics using relatively simplified facilities.

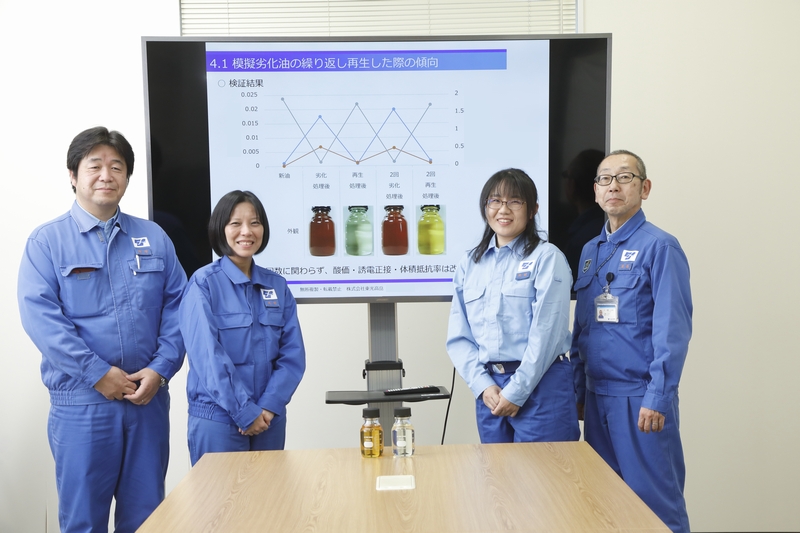

Recycling treatment by the adsorption method was verified using transformer oil for which deterioration had been artificially accelerated. As a result, we confirmed in the verification test that the standard for transformer oil was met, and the characteristics at a level approximated to new oil was obtained. Then, the same verification test was conducted for transformer oil actually used in pole-mounted transformers, which provided the same result. The research was presented to The Japan Petroleum Institute in 2022 and 2023.

Profile

-

Eriko KitamuraStrategic Technology Institute

Eriko KitamuraStrategic Technology Institute

Research & Development Center

Material Technology Group -

Mika OtakeStrategic Technology Institute

Mika OtakeStrategic Technology Institute

Research & Development Center

Material Technology Group Manager

Passion for practical application of recycled oil

KitamuraOur company manufactures and sells pole-mounted transformers mounted on the utility poles. Pole-mounted transformers are filled with transformer oil, which provides electrical insulation and cooling. The pole-mounted transformer is often repaired approximately every 10 years. In the repair process, a tank and a transformer core are collected and recycled if at all possible, but the transformer oil is replaced with new oil each time. I was wondering why the collected transformer oil could not be recycled as transformer oil, though it was thermally recycled as fuel in thermal power plants.

Therefore, I asked a person who was familiar with the transformer oil, and I learned that although the transformer oil was recycled in Japan, the used transformer oil had not been used as transformer oil again since the 1990s because PCBs, which are hazardous to humans and the environment, was detected in the recycled oil. However, because of the worldwide trend of environmental consciousness and the fact that all PCB contaminants must be disposed of in Japan by 2027, I feel that in the future, there is a high possibility that recycled oil will be able to be used domestically without having to worry about PCB contamination.

I was working in the electric equipment design department and then posted to the material technology group three years ago. I was happy to handle chemical materials in which I was originally interested because I graduated from the chemistry department at university. In the material technology group, I take charge of evaluating the compatibility of the transformer oil and equipment and analyzing the materials.

On the occasion of starting the research into recycled oil, I first deepened my knowledge of transformer oil. Whenever I had problems, I counted on an environment where I was free to consult my supervisors, including the material technology manager and the group manager (Ms. Otake), who were familiar with research in the recycled oil and environment-conscious materials.

OtakeI am the group manager in the material technology group and manage the research and development of members, including Ms. Kitamura. Since I used to research plant-derived resin materials and recycling, we have something in common, such as the approach to environmentally conscious materials research, and I sometimes discuss these issues together with Kitamura. Ms. Kitamura is a reliable person who has reliably conducted experiments herself and reported the result even without my detailed instructions.

Confrontation of various problems with team members toward practical application

KitamuraIn the research, we used the transformer oil which deterioration had been accelerated in a simulation of the environment of the pole-mounted transformer. Among some methods for recycling the transformer oil, we focused on the adsorption method by which recovery and improvement can be performed to a level that meets the quality requirements for transformer oil characteristics, using relatively simplified facilities. We treated the transformer oil for which deterioration had been accelerated by using five adsorbents with different characteristics. As a result, we found that activated clay used as an adsorbent in the recycling of edible oil was the most effective for recycling transformer oil.

In addition, we measured conductivity to determine the situation of recycling treatment. Since there was no precedent where a conductivity sensor was used in the verification of recycled oil, and the sensor itself had broad utility, we had a lot of trouble interpreting the measurements. In our interpretation of the results, it is important to understand not only the value itself but also the principle and mechanism in which the value was derived. After receiving advice from the material technology manager, supervisors, and senior staff and after surveying the previous literature and documents, I was able to fully understand the principles and mechanisms, which enabled me to successfully proceed with verification of the recycling treatment.

As an issue for commercialization, we also found that oxidation degradation was likely to occur in the recycled oil as recycling was repeated. Since the cause was that an original antioxidant component contained in the transformer oil decreased from the recycling treatment, a significant improvement could be expected by adding an antioxidant or an additive. From now on, it will be necessary to conduct experiments aiming to shorten the recycling treatment time and increase the recyclable number of times for commercialization and application to products in the recycled oil.

Approach to problems in environments and resources via Research and Development of recycled oil

KitamuraThe research results were presented at The Japan Petroleum Institute in 2022 and 2023. With many questions asked at the site, I knew much again about the attention brought to recycled oil in the industry.

I think my job is worthwhile when I get to know a verification result before everyone else. Since the recycled oil is not often researched by other researchers, I feel special pleasure in seeing the result.

In the future, with an eye toward realization of more advanced cyclic use of recycled oil, we will research and develop the appropriate recycling treatment technology to allow semi-permanent repetitive use.

Latest articles

-

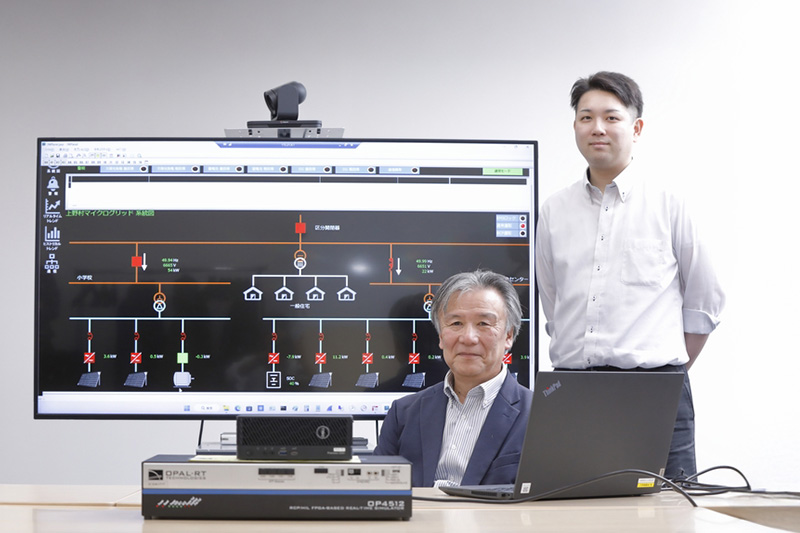

interviewBuilding a microgrid in Ueno Village, Gunma Prefecture, to Achieve Decarbonization and “Zero” Power Outages During a Disaster.The Sixth Strategic Energy Plan, a national policy, states that renewable energy is a main power source, and there is a need to expand the introduction of local power sources, including renewable energy. In recent years, the number of natural disasters in Japan has been on the increase, and a business continuity plan (BCP) is being emphasized for setting forth the methods and measures in advance to minimize the impact of an emergency and to ensure business continuity and a rapid recovery.

interviewBuilding a microgrid in Ueno Village, Gunma Prefecture, to Achieve Decarbonization and “Zero” Power Outages During a Disaster.The Sixth Strategic Energy Plan, a national policy, states that renewable energy is a main power source, and there is a need to expand the introduction of local power sources, including renewable energy. In recent years, the number of natural disasters in Japan has been on the increase, and a business continuity plan (BCP) is being emphasized for setting forth the methods and measures in advance to minimize the impact of an emergency and to ensure business continuity and a rapid recovery. -

interviewRecycling technology of transformer oil aiming to achieve carbon neutralityNowadays, the work involved in carbon neutrality and the establishment of a recycling society is essential in business activities. The same trend is observed in the field of transformer oil. The international standard for the quality of transformer oil has been revised; there is now no distinction in quality between new transformer oil and recycled transformer oil (hereinafter “recycled oil”) abroad, which allows them to be treated equivalently.

interviewRecycling technology of transformer oil aiming to achieve carbon neutralityNowadays, the work involved in carbon neutrality and the establishment of a recycling society is essential in business activities. The same trend is observed in the field of transformer oil. The international standard for the quality of transformer oil has been revised; there is now no distinction in quality between new transformer oil and recycled transformer oil (hereinafter “recycled oil”) abroad, which allows them to be treated equivalently. -

interviewWeCharge: EV charging management system that can be operated in large parking areasEfforts intended to achieve carbon-neutral levels have been made increasingly more often, which requires expansion of the EV charging infrastructure in order to propagate electric vehicles (hereinafter called “EV”).

interviewWeCharge: EV charging management system that can be operated in large parking areasEfforts intended to achieve carbon-neutral levels have been made increasingly more often, which requires expansion of the EV charging infrastructure in order to propagate electric vehicles (hereinafter called “EV”). -

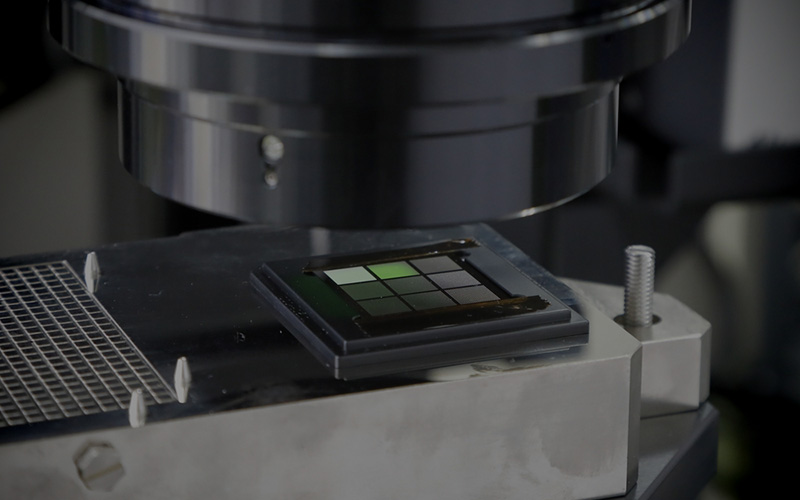

interviewThe confocal surface shape measurement system for semiconductor reliabilityIt is no exaggeration to say that semiconductors are used in everything supporting our lives and industry in modern society. Examples include smartphones, home appliances, and industrial products in various fields.

interviewThe confocal surface shape measurement system for semiconductor reliabilityIt is no exaggeration to say that semiconductors are used in everything supporting our lives and industry in modern society. Examples include smartphones, home appliances, and industrial products in various fields.